Miami Residents - Learn Lean Six Sigma’s History Here

Contact Us

Lean Six Sigma is a well-known manufacturing method that helped to overcome the Japanese industry’s dominance in the 80s. However, although it started in manufacturing, today, it is not only for businesses, but professionals and students are now recognizing the benefits it has for processes and systems. They can actually implement it into their daily lives to achieve personal growth and better results. We are committed to providing all details about this methodology at Lean Six Sigma Curriculum for Miami High School Students of Florida, and for it, we start with the 6 Sigma history.

We want you to pay attention to history because it will give you a great idea of how the methodology works and how it has grown over the past decade.

Let’s begin by saying that Lean Six Sigma is a blend of Japanese management principles with original methodologies such as Six Sigma and Lean—yes, they are individual methods—and can be traced back all the way to the United States.

Kaizen is a major influence in the field of methodology. It emphasizes cooperation and commitment while striving for customer satisfaction. This was one of the most important methods that allowed growth in the 1980s.

While other methods influenced LSS, it doesn’t mean that we have to look at each one to understand how history works.

Instead, let’s focus on the origins of Six Sigma and Lean and why LSS is still a viable option.

How LSS Was Originated from Lean & Six Sigma

Although Kaizen is the original concept, the inception and construction of LSS are based on other ideologies. It closely follows Lean and Six Sigma in terms of adapting and adding structures and principles to the process.

It is crucial to know the difference between Six Sigma and Lean. These are two distinct elements, but they were combined and shared some aspects.

Each is unique, but each has its own principles and basic concepts for the combined method that we are also focusing on.

Because of its structure and principles, Lean is often considered a way to reduce waste while increasing customer satisfaction. People often refer to Lean’s origins by referring to Toyota and its system.

Toyota was involved with the development of the system known as the Toyota Production System (or TPS). John Krafcik, a researcher at MIT who was involved in it from 1987 to 1988, contributed to the idea of Lean as well.

He was looking for a name to describe the TPS system. He wrote down the characteristics and differences of Toyota’s system to traditional production on a whiteboard. He concluded that Toyota’s system needs less of everything to create value.

This is how Lean Thinking was born quickly. Since its inception, it has been focusing on reducing waste and other activities that don’t add value.

Lean is built upon its own foundations and principles. Understanding your customer is crucial to understanding the process waste stream and all the productivity and benefits within the cycle. This is why Lean is more customer-focused in achieving results.

On the other hand, Six Sigma is an American-based method that has roots in the 1980s. Motorola founded Six Sigma in response to difficulties the company was facing with foreign companies at the time. Its CEO Bob Galvin had set a goal of tenfold improvement in five years.

The plan focused on global compatibility, improving participative management, quality, and productivity, as well as how to continually develop new strategies. Six Sigma was quickly adopted by Motorola, and all employees were trained to use it since the CEO was able to achieve results with the processes he set for the goal.

Six Sigma and Lean together recognize the importance of change and complement each other well when thinking about how it allows for growth.

But Where Does This Leave LSS?

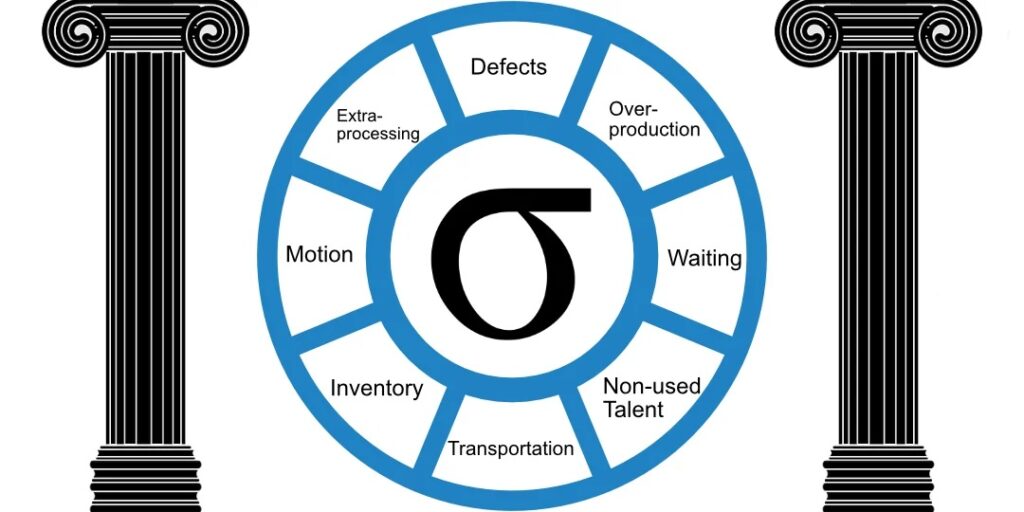

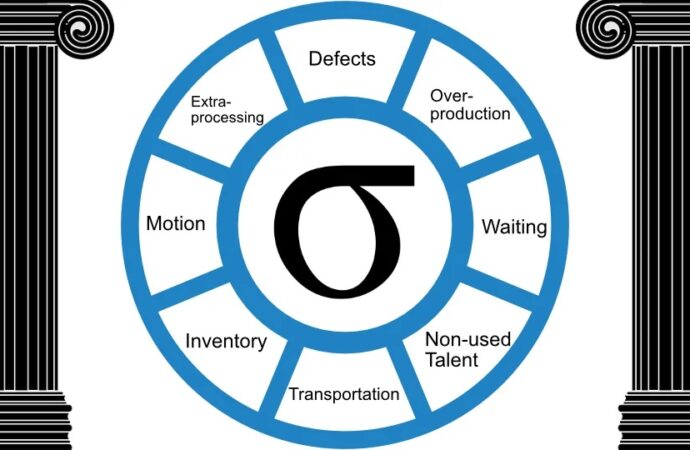

LSS has been used in many ways throughout history. LSS is designed to increase productivity and efficiency, reduce waste and improve quality. Practitioners have discovered ways to use it in other areas than manufacturing based on how both methodologies—the ones reviewed earlier—have influenced it.

After all, Lean helps employees and companies to better understand customers and prioritize their needs. They can then focus on the company’s value stream and processes to achieve perfection.

Six Sigma is committed to excellence and a system that encourages efficiency and clean operations. So, it is committed to continuous improvement and innovation.

Lean Six Sigma can be used to help students, professionals, businesses, and other individuals. It focuses on all the different methodologies, and thanks to the structure organized around it; it is possible to achieve all these results:

- Learn how to reduce waste.

- Increase efficiency.

- Reduce errors.

- The company will be less vulnerable.

- You can improve your time management.

- Lower costs lead to higher revenues and better wages.

- Get motivated.

- Leadership and innovation.

We Can Help

Contact our Lean Six Sigma Curriculum Pros of Miami team for more information. Our professionals will train your employees and students in the methodology to help them become problem-solvers, continuous improvement specialists, and team builders.

We want you to be able to reap all the benefits and feel valued at every job.